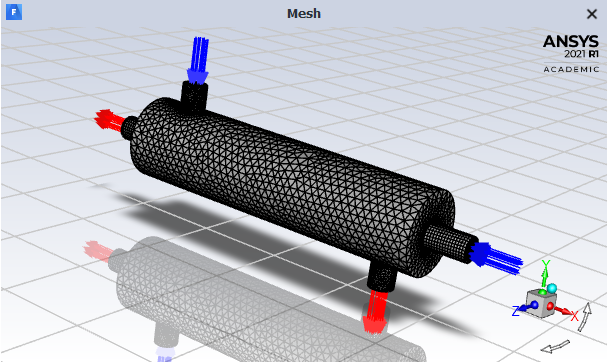

Conjugate Heat Transfer Analysis of Shell and Tube Heat Exchanger

Problem Statement:

It is an analysis of a Counterflow Heat exchanger, to cool the engine oil for a large industrial gas turbine engine. The water and oil enter the outer annulus and inner tube respectively.

CFD

Computational Fluid Dynamics (CFD) is the process of mathematically modelling a physical phenomenon involving fluid flow and solving it numerically using the computational process.

In a CFD software analysis, the examination of fluid flow by its physical properties such as velocity, pressure, temperature, density and viscosity is conducted. To virtually generate an accurate solution for a physical phenomenon associated with fluid flow, those properties have to be considered simultaneously.

A mathematical model of the physical case and a numerical method are used in a CFD software tool to analyze the fluid flow. For instance, the Navier-Stokes (N-S) equations are specified as the mathematical model of the physical case. This describes changes in all those physical properties for both fluid flow and heat transfer. A mathematical model varies by the content of the problem such as heat transfer, mass transfer, phase change, chemical reaction, etc. Moreover, the reliability of a CFD analysis highly depends on the whole structure of the process.

Theory:

Heat exchangers are devices that facilitate the exchange of heat between two fluids that are at different temperatures while keeping them from mixing with each other. Heat exchangers are commonly used in practice in a wide range of applications, from heating and air-conditioning systems in a household to chemical processing and power production in large plants.

The simplest type of heat exchanger consists of two concentric pipes of different diameters, called the double-pipe heat exchanger. One fluid in a double-pipe heat exchanger flows through the smaller pipe while the other fluid flows through the annular space between the two pipes. Two types of flow arrangement are possible in a double-pipe heat exchanger: in parallel flow, both the hot and cold fluids enter the heat exchanger at the same end and move in the same direction. In counterflow, on the other hand, the hot and cold fluids enter the heat exchanger at opposite ends and flow in opposite directions.